World Wide Suppliers of Industrial Sapphire&Ruby Precision Parts

Sapphire to Metal for Fluidic,Metrology&Medical Components

ISO 9001:2019 Mfg&Managment Certified Companies

-

- Sapphire Lens

- IPL Light Guides

- Sapphire Prism

- Zirconia Ceramic Parts

- Single Crystal Silicon Carbide(SiC 6H/ 4H)

- Optical Windows

- Optical Lens

- Sapphire Substrate&Wafer

- CMM Styli - Probe Tips

- Sapphire Orifice Jewel

- Sapphire Windows

- Jewel Bearing

- Sapphire Tube&Rods

- Balls&Semisphere

- Ruby Orifice Nozzle

- Sapphire&Ruby Assembly Parts

- Sapphire&Ruby Nozzle

- Custom Shaped Sapphire Parts

Products

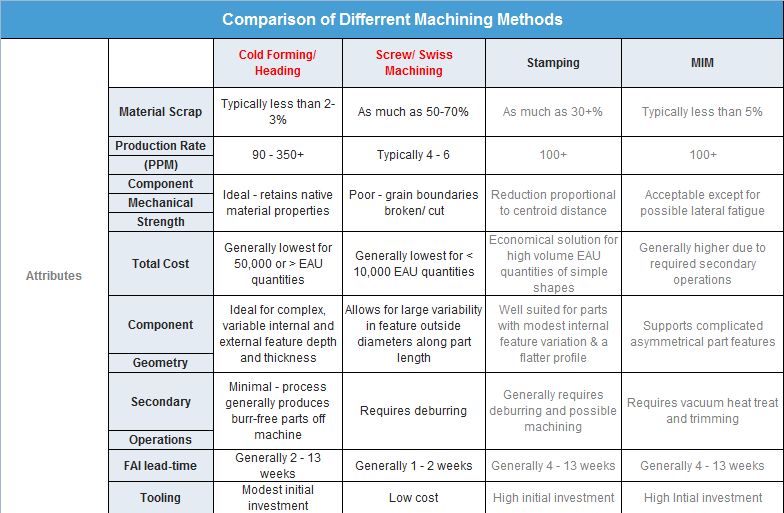

Cold forming or cold heading, is a manufacturing process where metal is worked at room temperature to create components and finished products,and is used to make a variety of goods including fasteners, car parts, and building supplies.

Cold forming has more advantages to other machining processes, such as screw machining.It poses

- Less waste

- Faster production

- Stronger parts

- Reduced costs

- Tight tolerances and critical specs

-

-

-

-

Material: Carbon Steel, Stainless Steel, Brass,Bronze Aluminum

Tolerances:0.02mm in diameter,0.1mm in length

Machining Process:

- Cold Forging, Cold Heading

- Roll forming

- Roll threading,

- Tapping

- Broaching

- Grinding

- Turning/Shaving

- Slotting/Sawing

- Reheading

- Knurling

- Finishing

- Burnishing

- Assembly

- Trimming

- Drilling

- Milling

- Flattening

Surface Treatment: Polishing, Heat Treatment, Sand Blasting, Zinc Plated, chemical Film,

Packing: Carton Box, Blister tray, Pallet, Wooden Case.

Certificate:ISO9001:2008

Custom Cold Heading Parts Application:

Systems of Suspension, Brake, Engine, Clutch, Chassis, Exhaust, Cable and many other industries.

Such as:

Application: Airbag mount assembly

Component: Attachment pin

Application: Automotive brake assembly

Component: Piston rod

Application: Door lock

Component: Dead bolt

Application: Steering system

Component: Shaft with involute spline

Application: Motorcycle wheel assembly

Component: Internally-threaded fastener for

attachment of wheel spokes to tire rim

Application: Automotive engine assembly

Component: Pipe plug housing requiring smooth threads

to accept O-ring assembly; also, bottom of cup must be

flat to .05" and first step in cup must be smooth

Application: Commercial air conditioner

Component: Valve stem

Machining Tolerances

Normally the diameters tolerance is ± 0.05mm. Length tolerance is ±0.1mm.on demands, we can also achieve: diameters tolerance is ±0.02mm.Length tolerance is ±0.05mm Material Selection: Normally used carbon steel 35# or 45# ,Stainless Steel:304 or 316.According to customer requirement use Aluminum and Brass

Surface Treatment

Heat treatment, Zinc Plated, Zinc-Nickel Alloy Plated, Chrome Plated

|

|

|

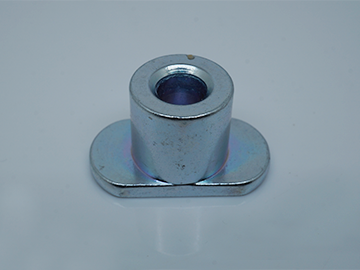

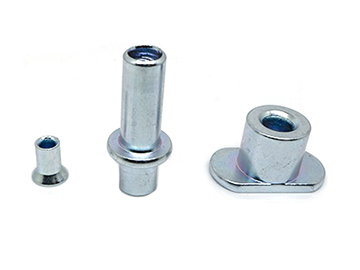

Flange Protector |

Flange Shapes |

|

|

|

Non-concentric Flange Bolts |

Flange Bushing |

|

|

|

Solid Cold Foring Parts |

|

1803,2006,Huachuang Building

1803,2006,Huachuang Building

0086 18623135040

0086 18623135040

13500373464

13500373464